Meet the Last Home Goods Manufacturers in America

Most home goods sold in the U.S. today are manufactured in overseas factories. However, a handful of manufacturers still operate within the country and maintain domestic production despite decades of economic pressure. They work with local materials, support American jobs, and make products built to last.

Oka Brands

Credit: Instagram

In Buford, Georgia, Oka Brands assembles its footwear, though some materials and components are imported. The company encourages customers to return worn-out shoes through its recycling program, which helps reduce waste in landfills. Although the exact amount of diverted material has not been independently verified, the approach reflects a broader focus on sustainability and circular design.

American Giant

Credit: Instagram

Price isn’t the main selling point for American Giant. Their hoodie costs $168, but it’s meant to last for years. Buyers are encouraged to consider how often they’ll wear something before replacing it. Founder Bayard Winthrop talks about cost per use instead of sticker price. This strategy works best with basics like sweatshirts and T-shirts, where durability is a key consideration.

Liberty Tabletop

Credit: Instagram

Flatware was once a huge American industry. Now, Liberty Tabletop claims to be the only one left making it in the U.S. It runs its factory in Sherrill, New York, and sources all its steel from domestic suppliers. During the COVID-19 pandemic, web sales rose by more than 200%, thanks to local production and fast delivery.

Vermont Flannel

Credit: Instagram

Vermont, the Vermont Flannel Company has made its shirts from 100% American-milled cotton since the early 1990s. Every product is cut and sewn in the U.S., and the fabric is brushed on both sides for softness and durability. Unlike many apparel makers, they’ve never shifted production abroad and cited quality and job preservation as core reasons.

Gat Creek

Credit: Instagram

Wood for Gat Creek furniture comes from nearby forests. The corporation operates in Berkeley Springs, West Virginia, and uses American hardwoods for its entire line. Founder Gat Caperton never sent production overseas, although he now pays more for imported components, such as drawer glides and knobs. Still, the primary materials and assembly stay local.

Nordic Ware

Credit: Instagram

The Bundt pan is more than a nostalgic kitchen staple because Nordic Ware still manufactures it, right where it all began. The company was founded in 1946, and it remains family-run to this day. Jennifer Dalquist, the founders’ granddaughter, has explained that they chose to keep manufacturing in Minnesota after seeing troubling conditions overseas, including low wages, weak labor standards, and serious environmental risks.

American Blossom Linens

Credit: Instagram

When American Blossom Linens launched its consumer line in 2019, it had no idea how well-timed the move would be. The parent company, Thomaston Mills, had already been making linens for hospitals and institutions. However, with a new retail site up and running just before the pandemic, it experienced a surge in demand when global shipping slowed.

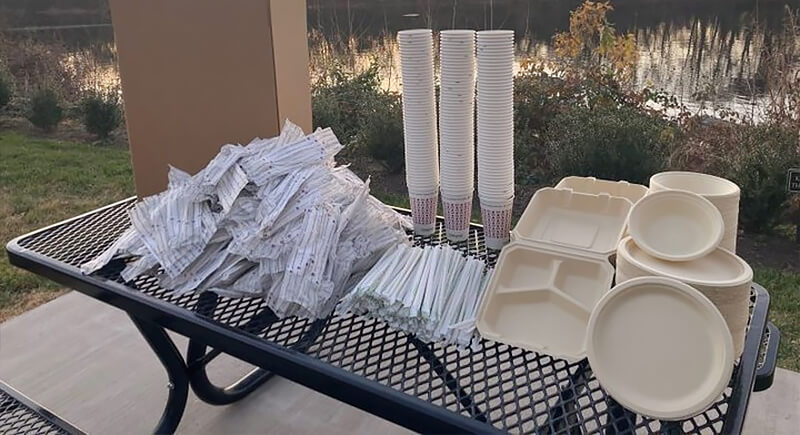

Terravive

Credit: Instagram

Plastic utensils rarely get a second thought, but Terravive built a business on replacing them. Headquartered in Richmond, Virginia, the company manufactures compostable food-service products at U.S. facilities, though not all materials are sourced domestically. Founder Julianna Keeling started the company in her garage, focused on scaling sustainable alternatives for everyday disposables.

American Roots

Credit: Instagram

Focusing on full control over production, the operation in Portland, Maine, keeps every step, from cutting to finishing, under one roof. Union labor at American Roots makes the apparel using American-sourced materials. The founders came out of labor organizing and aimed to restore local textile jobs. That commitment influences every choice, including pricing and growth.

Los Angeles Apparel

Credit: Instagram

Founded in 2016 by Dov Charney, the former CEO of American Apparel, Los Angeles Apparel was built to revive homegrown garment production in the city. Charney reopened a vertically integrated factory where cutting, sewing, dyeing, and packing all happen on-site. The business focuses on wardrobe staples like T-shirts and sweatshirts while paying above-average wages.